Established in 1973 by Eray Üstün. Üstün Makine began its activity as a family workshop dedicated to basic stamping processes. Today, we operate a 4,000 m² plant equipped with advanced manufacturing technology, from which we supply high-precision metal components to Tier 1 automotive manufacturers worldwide. Our experience accumulated over five decades positions us as specialists in high-volume cold stamping, design and construction of progressive dies, as well as value-added assembly processes, meeting the highest quality standards of the automotive sector.

Skilled Workforce

Manufacturing Space

Eray ÜSTÜN founded the company to manufacture car lighters under license from an Italian manufacturer.

Üstün Makine Ltd. established a mass assembly line dedicated to lighters, supplying products to the spare parts market throughout Turkey.

Tofaş (Fiat) approved Üstün Makine as the exclusive OEM supplier of lighters for its production line in Bursa.

Oyak Renault certified Üstün Makine for a new line of lighters for Renault vehicles manufactured in Turkey.

Other Turkish OEMs, including Karsan Peugeot, Anadolu Isuzu, and Temsa, selected Üstün Makine as a reliable supplier of lighters for local vehicle assembly.

As Turkey integrated into the global automotive supply chain, Üstün Makine gradually phased out lighter production.

Autoliv designated Üstün Makine as a strategic supplier of a deep-drawn component used in the production of seat belts at its Gebze plant, consolidating a key collaboration in the automotive safety sector.

Tuğrul Ustun took over management of the plant and began transforming it into a manufacturer specialized in cold-stamped metal parts.

Üstün Makine became part of Spain’s Teknia group, initiating a new era full of challenges, growth, and continuous improvement in our production processes.

During its integration into the Teknia group, the plant increased its technological capacity in cold stamping processes, strengthening its position as a strategic supplier to international Tier 1 manufacturers.

In 2025, the Teknia Gebze plant was reacquired by its director, Tugrul Ustun, in collaboration with a strategic industrial partner. This transition ensured operational continuity, job stability, and the recovery of its autonomy, returning to its original name:

ÜSTÜN GEBZE MAKİNE SAN. TİC. A.Ş.

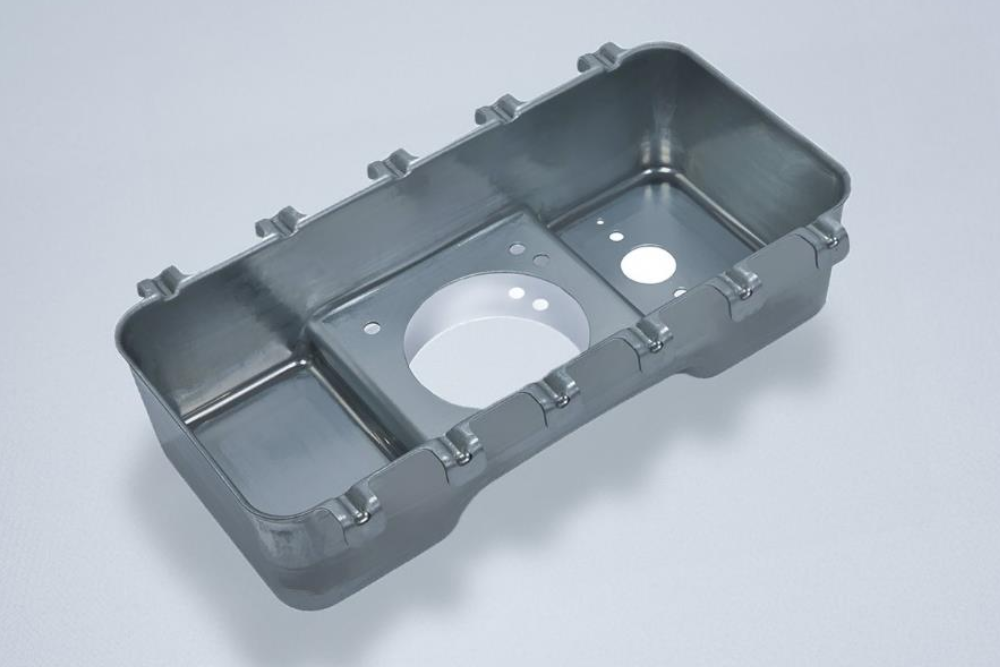

Over 40 years of experience validate our expertise in deep drawing and metal stamping for sheet metal part manufacturing.

High-speed production of complex parts with tight tolerances using over 50 progressive dies.

Specialized in the production of deep-drawn components for seat belts, airbags, inflators, seals, exhausts, and seat parts.

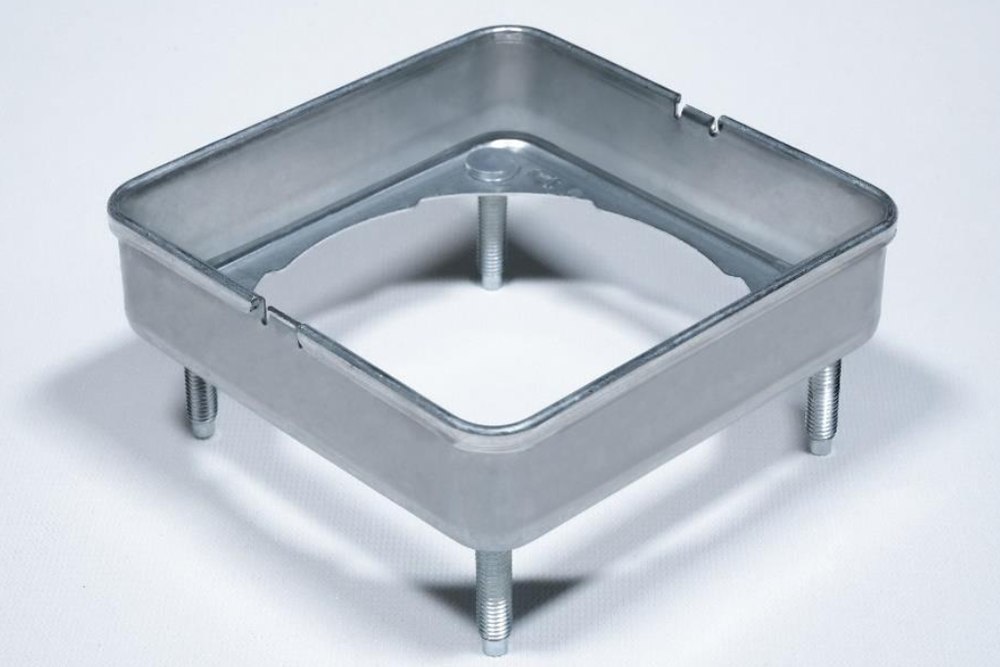

Complete subassembly services including welding, fastening, and finishing.

We develop functional prototypes and manufacture progressive, transfer, and manual dies tailored to each stage of the industrial process, from initial validation to mass production. Our engineering team applies simulation tools, CAD/CAM design, and dimensional control to ensure precision, reliability, and repeatability.

We accelerate product development through rapid prototyping services that integrate design, manufacturing, and validation. We offer solutions tailored to each phase of the development process.

Our in-house tool and die shop produces high-precision dies with fast delivery times and exceptional durability.

We manufacture using a digitally integrated system within our processes. This allows us to optimize mass production efficiency and ensure superior quality through preventive maintenance that prevents unexpected errors.

Our production lines integrate smart automation that adapts to material variations in real time, ensuring consistent quality.

Continuous monitoring and data analysis optimize each stamping operation for maximum precision and minimum waste.

We combine traditional craftsmanship with modern smart technology to deliver products that meet the highest industry standards.

Live dashboards track press performance, cycle times, and production metrics across all equipment.

IoT systems enforce FIFO material flow, reducing waste and ensuring part freshness throughout production. Each batch is digitally tracked, providing full process visibility from raw material to finished product.

Smart sensors optimize energy consumption in presses, reducing costs by up to 20%.